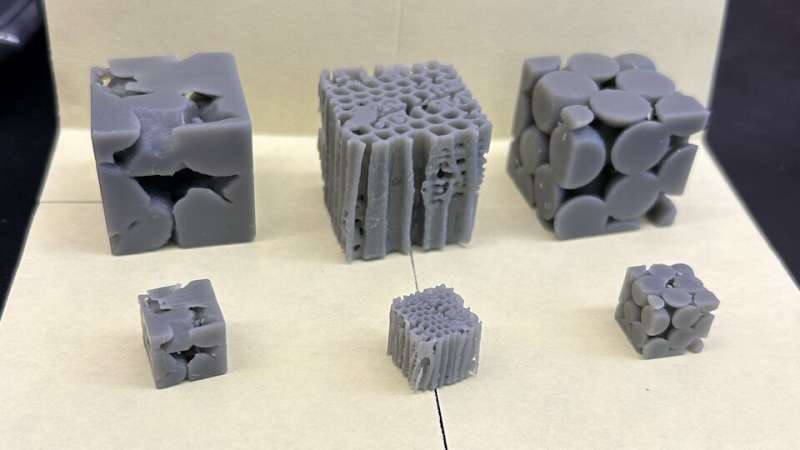

The cubes’ internal structures are based on different porous materials, including bone and wood.

by Maddie Go, Duke University

Advances in artificial intelligence for porous materials design could impact a wide variety of fields, from orthopedic implants to next-generation batteries.

The world is full of holes. Bones, rocks, wood, concrete…look at any of these materials close enough and you’ll see that their structures contain tiny pockets of empty space. And these pockets are random: they’re less like the perfectly identical cubes in an ice tray and more like the variable pits and tunnels found in Swiss cheese.

These small holes pose a big challenge for engineers who want to predict how porous materials will behave under a variety of different design circumstances.

For example, bones are a crucial material to consider when developing prosthetic limbs and implants, especially ones that attach directly to the skeleton. Rocks, wood and concrete are all important elements when it comes to constructing buildings. Whether these materials are bearing the load of a single hospital patient or an entire apartment complex, engineers need to know how they’ll perform under physical stress.

A group of Duke researchers have published a set of papers that explored a solution to this challenge with the help of AI. The collaboration is co-led by Laura Dalton, assistant professor of civil and environmental engineering; Manolis Veveakis, professor of civil and environmental engineering; and Ken Gall, professor of mechanical engineering and materials science.

Two of the papers were published in Communications Engineering and ACS Omega, and the third in Philosophical Transactions of the Royal Society A.

“The results of these papers make me hopeful and excited!” Dalton remarked. “AI is allowing us to identify material behavior patterns at a rapid pace that humans simply would not be able to match.”

In the world of materials research, one mathematical theorem has long suggested that four features of a porous material’s microstructure can provide a complete description of its properties.

These include porosity, or how much empty space there is inside the structure; internal surface area, or how much surface area is exposed by said empty space; mean grain size, or how big the solid parts of the structure are on average; and connectivity, or how connected the solid parts are to one another.

The researchers put this theorem to the test. In the Communications Engineering paper, led by Veveakis’ former lab Ph.D. student Winston Lindqwister, they fed images of porous structures to an AI and asked it to find any features it could use to predict their strength.

The AI identified 35 different features that, when used together, accurately predicted the results of real-world strength tests with 3D-printed physical samples that were conducted by former Gall lab Ph.D. student Jacob Peloquin.

Next, the researchers asked another AI to make the same strength predictions using only the classic theorem’s four features. The accuracy of this AI turned out to be about as good as that of the 35-feature AI, suggesting that the theorem held true: these four key features alone were enough to effectively predict the strength of a porous material.

“One of the earliest ideas I came across in my research career was that, if we can determine the key features that govern about 90% of an observed phenomenon, then we can properly design and maintain a system for that phenomenon that does what we want it to do,” Dalton said. “So the fact our results suggest that we can simplify a complicated design challenge to four features is remarkable.”

“If we can reliably predict a majority of a material’s response based on just a few structural features, we can dramatically streamline the design process,” Lindqwister said. “Combined with technologies like 3D printing, this gives us unprecedented control over how we tailor structures to meet specific goals.”

With this streamlined model in mind, the researchers then sought to build an AI that could solve the inverse problem: If given a desired strength, could the AI predict the features of a porous material that would have that strength?

In the Philosophical Transactions of the Royal Society A paper led by Ph.D. student QinYi (Emma) Tian in the Dalton lab, the researchers trained an AI to process the strength data of an unknown porous material and predict what that material’s four key features might look like. Then the researchers 3D-printed physical samples based on those predictions and crushed them to confirm that their strengths matched up.

“The AI model showed strong potential in reliably predicting the four features needed for a given strength,” Tian said. “This is promising because models like this could be applied to a lot of practical engineering and design problems.”

The researchers also investigated if AI could use these same four features to predict properties other than strength. In the ACS Omega paper led by Lindqwister, they found AI could predict how well the internal structures of porous materials facilitate certain chemical reactions, which is important for battery design.

More information:

W. Lindqwister et al, Predicting compressive stress-strain behavior of elasto-plastic porous media via morphology-informed neural networks, Communications Engineering (2025). DOI: 10.1038/s44172-025-00410-9

Winston Lindqwister et al, Chemical Homogenization for Nonmixing Reactive Interfaces in Porous Media, ACS Omega (2025). DOI: 10.1021/acsomega.5c00641

Learning Latent Hardening (LLH): Enhancing Deep Learning with Domain Knowledge for Material Inverse Problems. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences. DOI: 10.1098/rsta.2024.0043. On arXiv: DOI: 10.48550/arxiv.2501.10481

Source: https://phys.org/news/2025-08-pressure-ai-porous-materials.html